Workshop professionals know that squeaking brakes don’t always mean something serious. A closer look at the braking system is nevertheless necessary, especially after a brake repair. For the devil sometimes lurks in the details.

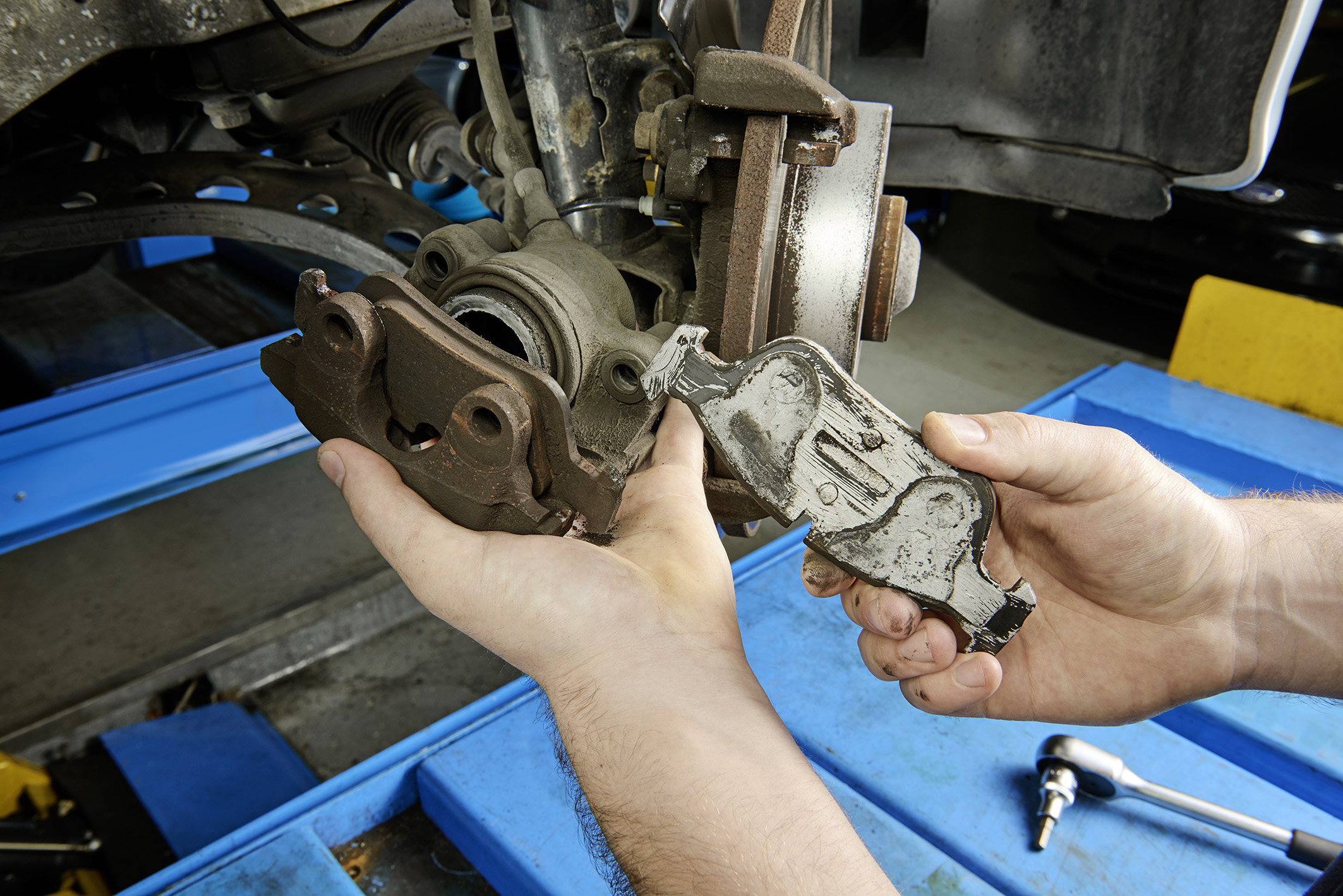

If a customer comes to your workshop with squeaking brakes, this usually means that you start searching for clues as to what’s wrong. First of all though, all the components have to be thoroughly cleaned. This makes it easier for you to perform a check of the different components, which is also very important: Are the pistons and caliper smooth-running, are there any increased sliding forces on the brake caliper? Are there any traces of wear in the suspension parts, or are cracks visible in the rubber components? Even a brake disc or wheel hub that isn’t running exactly flat can cause noise or other comfort issues. This is where precise remeasurement is required.

Repairing the braking system – system error?

Fortunately, the problem can be solved quickly if it’s only dirt in the braking system that’s causing the unpleasant background noise. Sometimes the squeaking noise also occurs shortly after a brake repair, so it’s important to take a very close look at the braking system. Because there’s one thing you should always keep in mind in your workshop: Brakes and chassis must always be seen as a complete system. The defect or the replacement of a component therefore affects the entire system.

Brake maintenance requires care and cleanliness

However, regardless of whether you’re still looking for the reason why the brakes are squealing or you’re already installing new parts, the two ‘musts’ for any work on the braking system are utmost diligence and cleanliness. This is all the more important today, since modern braking systems are increasingly being designed for lightweight constructions, so they react to even the smallest changes. An incorrectly cleaned wheel hub, a rusted brake caliper shaft or incorrect lubrication during assembly can lead to some unpleasant complaints. It’s the same story here: The defects devil often lurks in the fine details – so clean and accurate work is absolutely essential.

Any Questions?

Our experts on the Continental Serviceline will be happy to assist you and provide you with all the technical information you need. Outside of office hours, we would be happy to receive an e-mail at ate.hotline@continental-corporation.com.

Do you want to be regularly informed about exciting topics in the aftermarket? Subscribe to the newsletter